|

INNOVATION WITH ELECTROCERAMICS |

|

Sodium battery technology > Ceramic-metal welding

|

||||||||||||||||||||||||||||

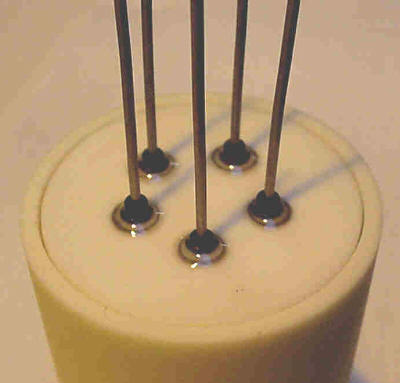

Ceramic-metal weldingIonotec can provide expertise in bonding techniques which are particularly suitable where hermetic or vacuum-tight joints are required:

Examples of ceramic-metal welding include

Thermocompression bonding

Ultrasonic welding

Ultrasonic welding is a fast process that can be used for bonding dissimilar metals and for ceramic-metal welding. Some advantages of the ultrasonic method are:

Not all materials are suited to ultrasonic welding, especially if they have low mechanical strength. In such cases thermocompression bonding may be preferable.

Examples of ultrasonically weldable metal-metal couples

| ||||||||||||||||||||||||||||

Sodium battery technology > Ceramic-metal welding

|

The contents of this Web site are presented for information purposes only. Ionotec has endeavoured to ensure its accuracy but makes no guarantee concerning the products or services described herein, nor their usage in or applicability to particular situations. Ionotec accepts no liability for the consequences of the use by others of any information acquired or accessed via the Ionotec Web site. Ionotec reserves the right to change or modify the contents of its Web site at any time without notice.

©2013 Ionotec Ltd

Ionotec Ltd is registered in England, number 3141009

Registered Office and Trading Address: 14 Berkeley Court, Manor Park, Runcorn, Cheshire WA7 1TQ, UK

Time in London

Time in London