|

INNOVATION WITH ELECTROCERAMICS |

|

Sodium battery technology > Ceramic coatings

|

||||||||||||||||

Ceramic coatings

Protective coatingsIonotec produces conductive, resistive and insulating coatings on ceramic and metal substrates tailored to specific needs, such as:

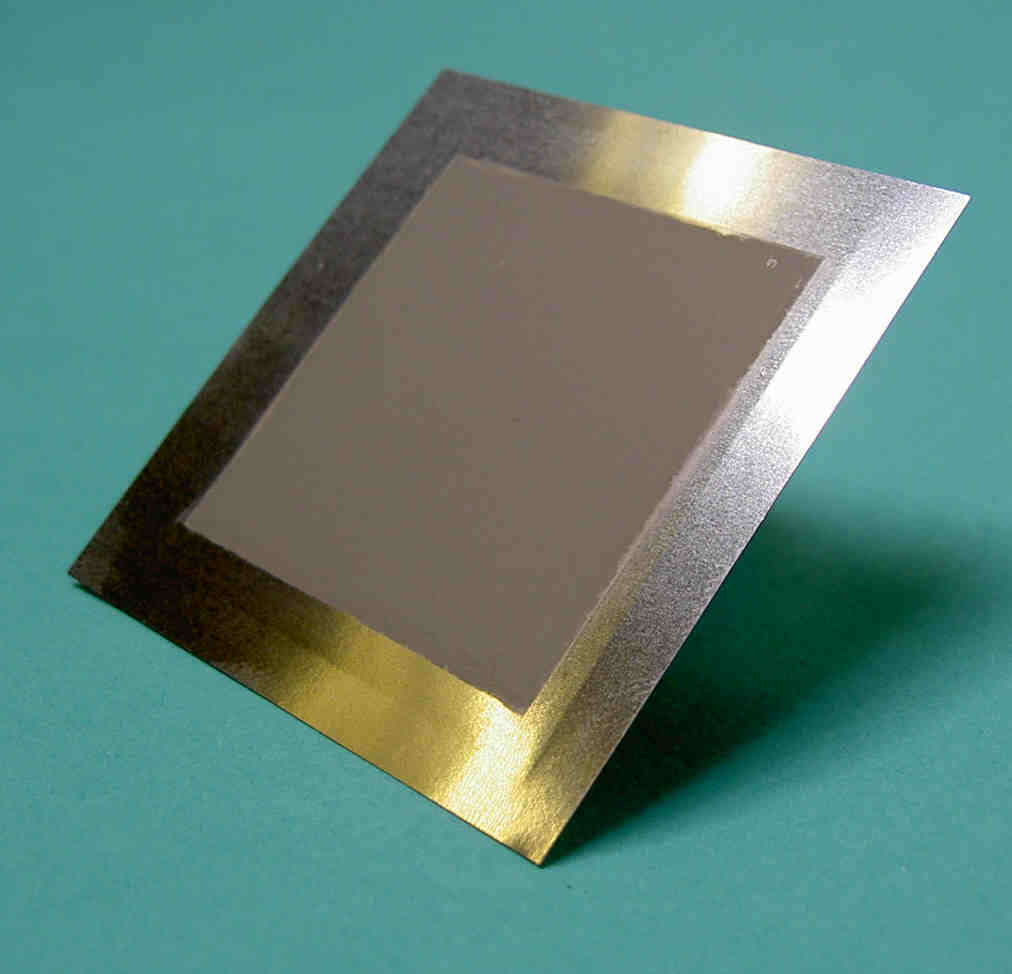

Conductive membranesSome applications such as solid oxide fuel cells (SOFCs) require conductive thick-film layers designed to operate at high temperatures as solid electrolytes or as electrodes. The ceramic coatings can be made either fully dense or intentionally porous, and stacked on slotted metal substrates as shown in this membrane electrode assembly.

Ceramic coatings such as zirconium oxide on metal foil can be made either electrically insulating or electrically conductive by doping treatments, incorporation of a metallic component, and appropriate firing treatments. ElectrodesThere are also low-temperature applications such as the surface treatment of conventional electrodes in order to limit corrosion and to provide stable performance in electrolysis. Identifying cost-effective alternatives to conventional noble-metal electrodes such as platinum is becoming increasingly important without loss of the characteristics important to successful electrode operation

Solving such problems demands considerable expertise in materials chemistry which we may be able to help with. Please contact us to discuss your application in confidence.

Examples of coatings

Examples of substrates

| ||||||||||||||||

Sodium battery technology > Ceramic coatings

|

The contents of this Web site are presented for information purposes only. Ionotec has endeavoured to ensure its accuracy but makes no guarantee concerning the products or services described herein, nor their usage in or applicability to particular situations. Ionotec accepts no liability for the consequences of the use by others of any information acquired or accessed via the Ionotec Web site. Ionotec reserves the right to change or modify the contents of its Web site at any time without notice.

©2013 Ionotec Ltd

Ionotec Ltd is registered in England, number 3141009

Registered Office and Trading Address: 14 Berkeley Court, Manor Park, Runcorn, Cheshire WA7 1TQ, UK

Time in London

Time in London